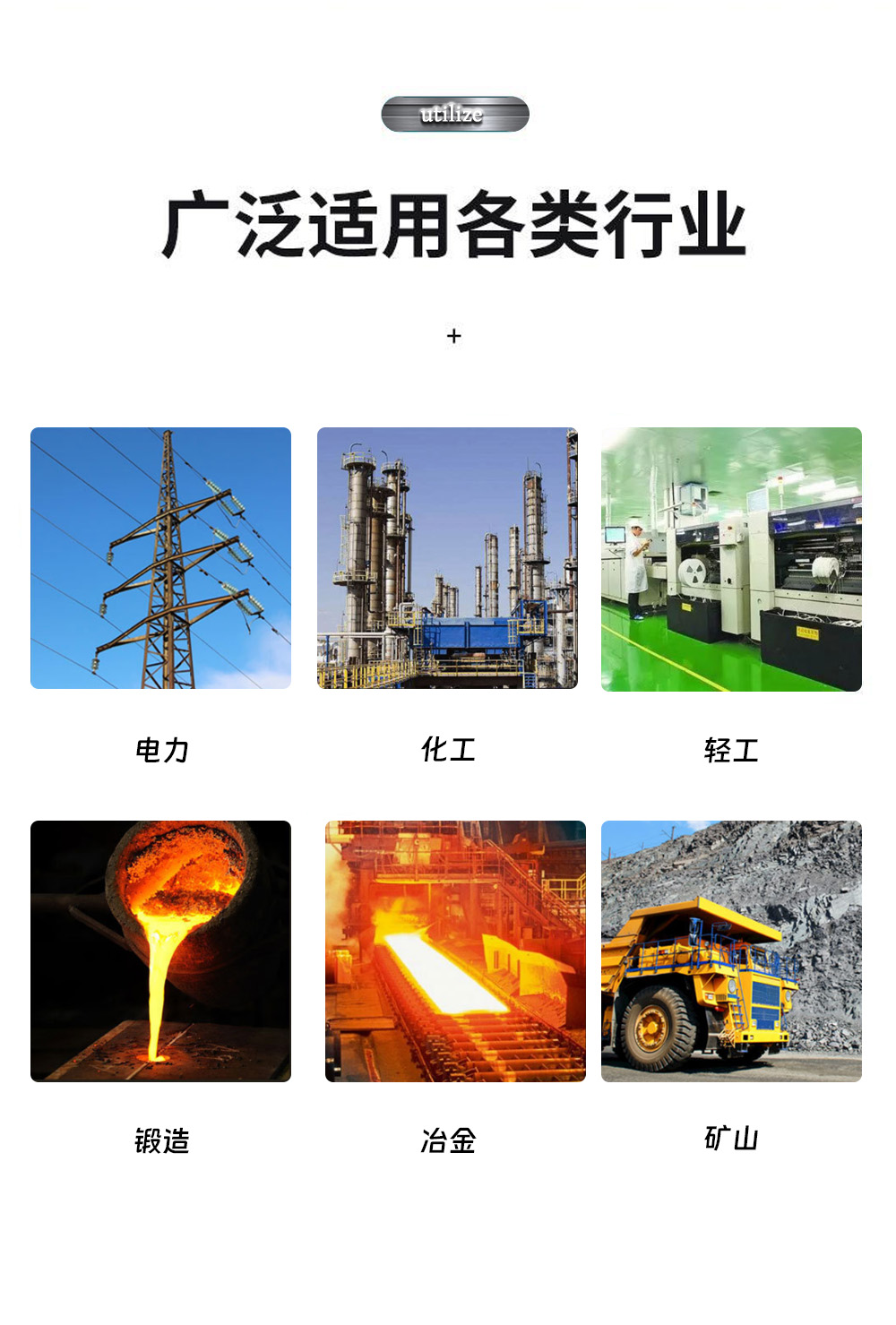

It is widely used in vibration equipment in mining, metallurgy, building materials, chemical industry, electric power and other industries, such as vibrating screens, vibrating conveyors, vibrating feeders, vibrating crushers, vibrating balers, vibrating shakeouts, vibrating molding machines, vibrating pile drivers, vibrating elevators, vibrating filling machines, vibrating arch-breaking and anti-blocking devices for silos, etc.

XVB-21-4 three-phaseHorizontal vibrating motorIt is a vibration motor produced by Xinxiang City Binhe Motor Co., Ltd. The following is its relevant introduction:

rated power: 1.6 kW

Rated voltage: 380 volts

Rated frequency: 50 Hz

Rated current: 3.82 amps

Protection grade:IP55

insulation class:F

exciting force: 21 thousand cattle

number of poles: 4 poles

Rated speed: 1440 rpm

Integrated casting of casing and frame: Adopt an integrated chassis and basecastingThe technology strengthens the sealing performance of the whole machine and can effectively prevent dust, debris, etc. from entering the interior of the motor. It is suitable for working environments with multiple dust and multiple particulate materials.

adjustable eccentric block: Install a set of adjustable eccentric blocks at both ends of the rotor shaft to adjusteccentric blockThe position and angle of the exciting force can be flexibly changed to meet the working needs of different vibration equipment and achieve stepless adjustment.

When three-phase alternating current passes through the three-phase windings in the stator, a rotating magnetic field is generated, which cuts spatial magnetic lines of force between the stator and the rotor, thereby inducing a rotating electromagnetic torque on the rotor and driving the rotor to rotate. At the same time, due to the eccentric mass on the rotor, centrifugal force will be generated during the rotation process, which in turn generates vibration force, which can be transmitted to the vibration equipment to cause it to produce vibration motion.

It is widely used in vibration equipment in mining, metallurgy, building materials, chemical industry, electric power and other industries, such as vibrating screens, vibrating conveyors, vibrating feeders, vibrating crushers, vibrating balers, vibrating shakeouts, vibrating molding machines, vibrating pile drivers, vibrating elevators, vibrating filling machines, vibrating arch-breaking and anti-blocking devices for silos, etc.

XVB-21-4 three-phaseHorizontal vibrating motorIt is a vibration motor produced by Xinxiang City Binhe Motor Co., Ltd. The following is its relevant introduction:

rated power: 1.6 kW

Rated voltage: 380 volts

Rated frequency: 50 Hz

Rated current: 3.82 amps

Protection grade:IP55

insulation class:F

exciting force: 21 thousand cattle

number of poles: 4 poles

Rated speed: 1440 rpm

Integrated casting of casing and frame: Adopt an integrated chassis and basecastingThe technology strengthens the sealing performance of the whole machine and can effectively prevent dust, debris, etc. from entering the interior of the motor. It is suitable for working environments with multiple dust and multiple particulate materials.

adjustable eccentric block: Install a set of adjustable eccentric blocks at both ends of the rotor shaft to adjusteccentric blockThe position and angle of the exciting force can be flexibly changed to meet the working needs of different vibration equipment and achieve stepless adjustment.

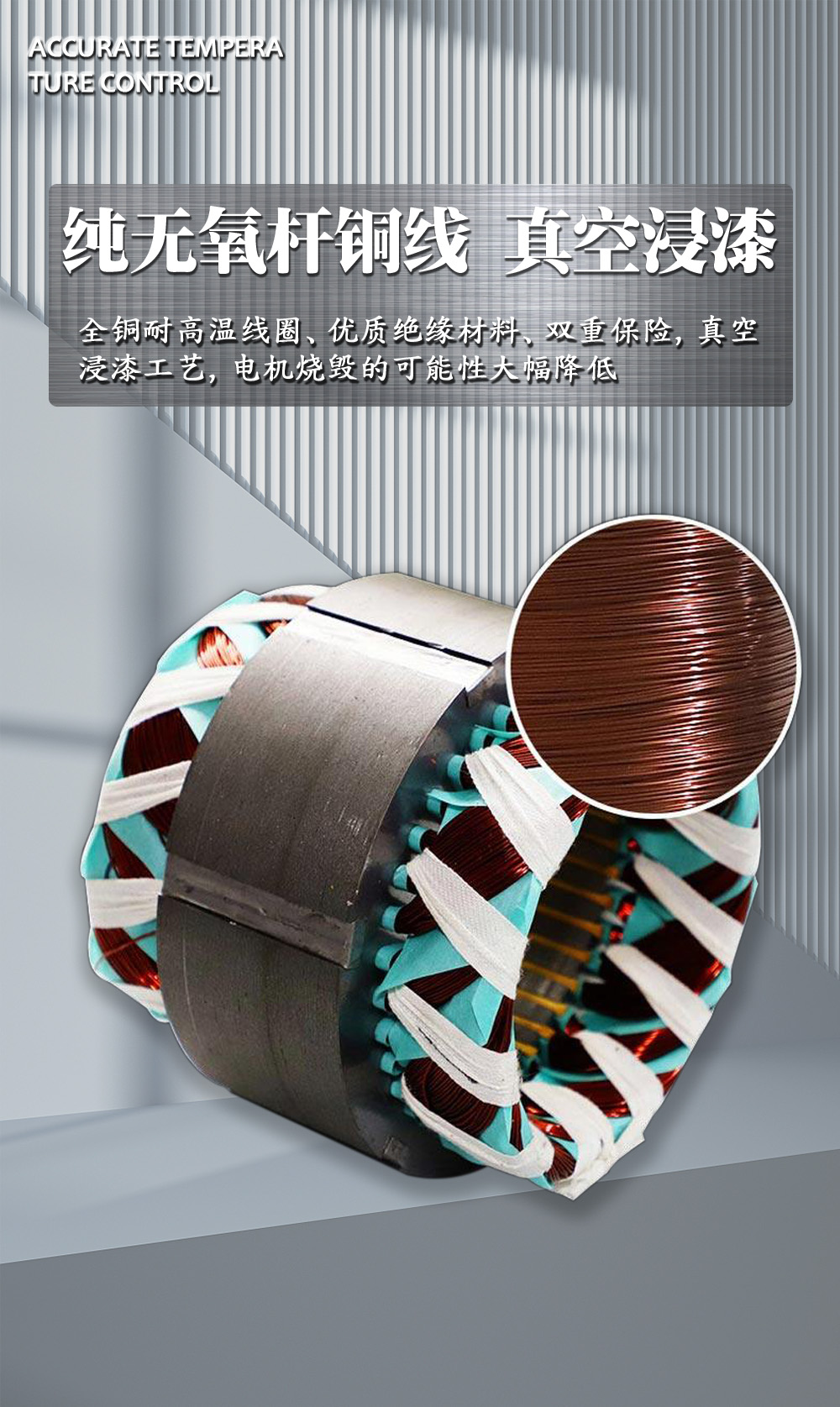

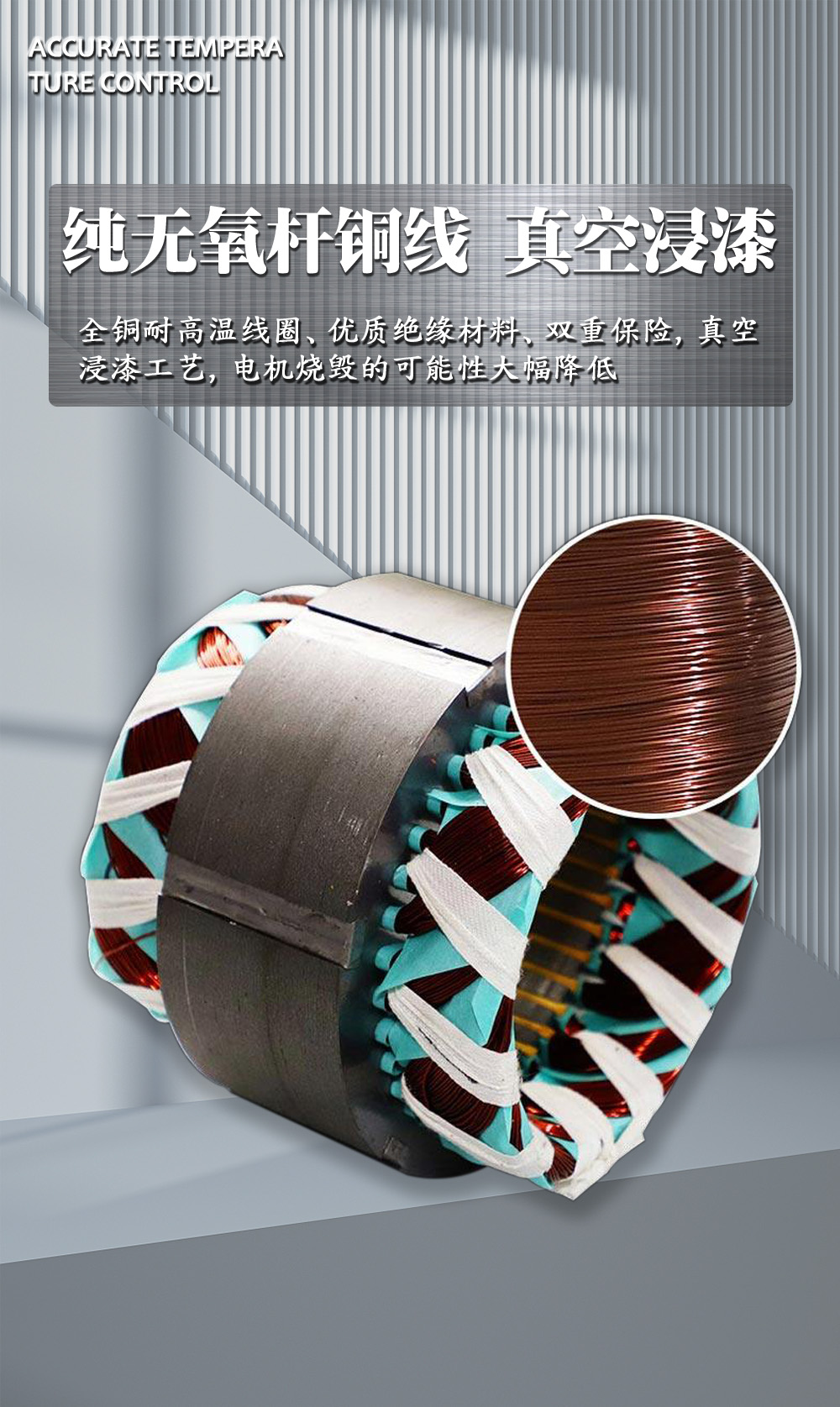

When three-phase alternating current passes through the three-phase windings in the stator, a rotating magnetic field is generated, which cuts spatial magnetic lines of force between the stator and the rotor, thereby inducing a rotating electromagnetic torque on the rotor and driving the rotor to rotate. At the same time, due to the eccentric mass on the rotor, centrifugal force will be generated during the rotation process, which in turn generates vibration force, which can be transmitted to the vibration equipment to cause it to produce vibration motion.

It is widely used in vibration equipment in mining, metallurgy, building materials, chemical industry, electric power and other industries, such as vibrating screens, vibrating conveyors, vibrating feeders, vibrating crushers, vibrating balers, vibrating shakeouts, vibrating molding machines, vibrating pile drivers, vibrating elevators, vibrating filling machines, vibrating arch-breaking and anti-blocking devices for silos, etc.