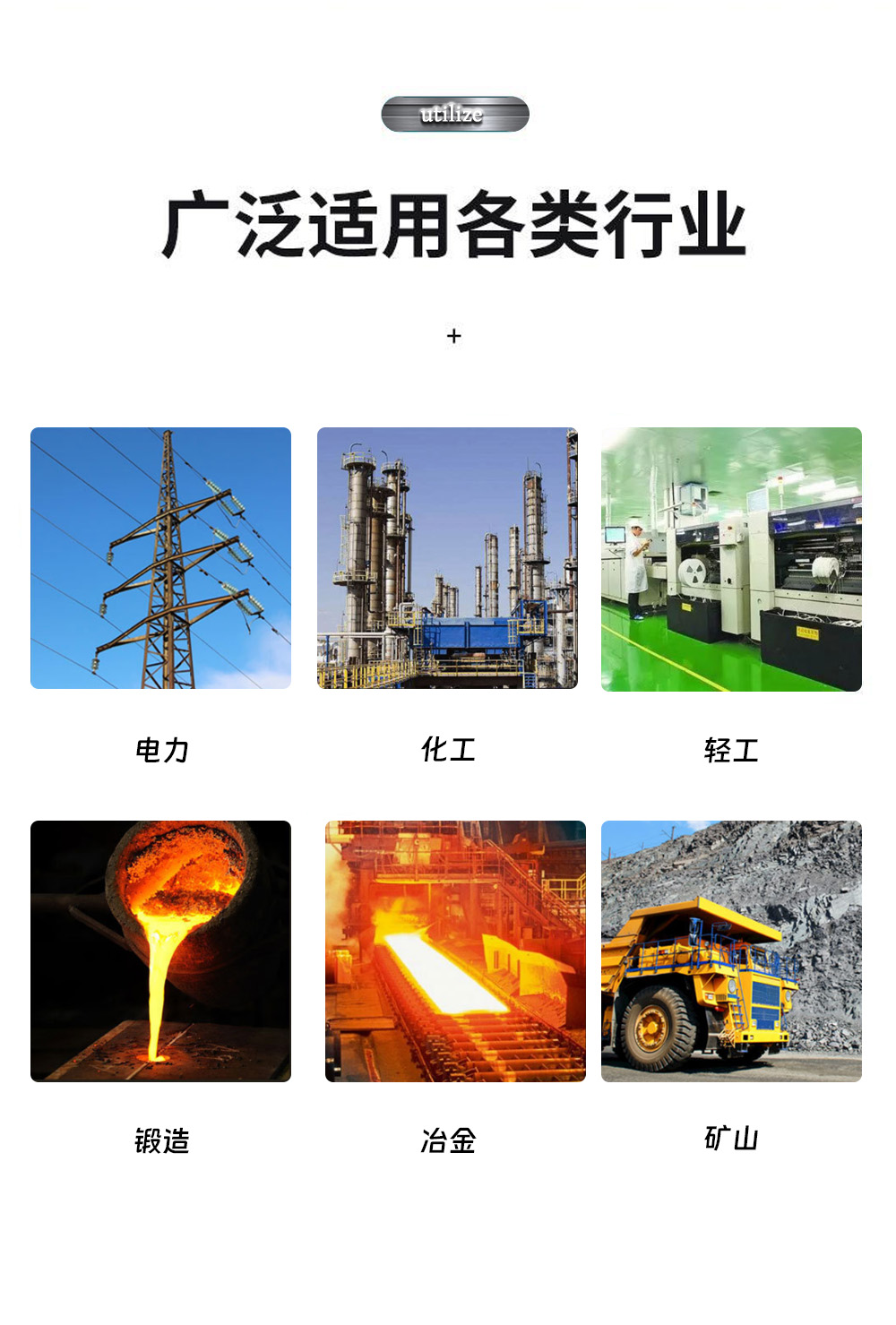

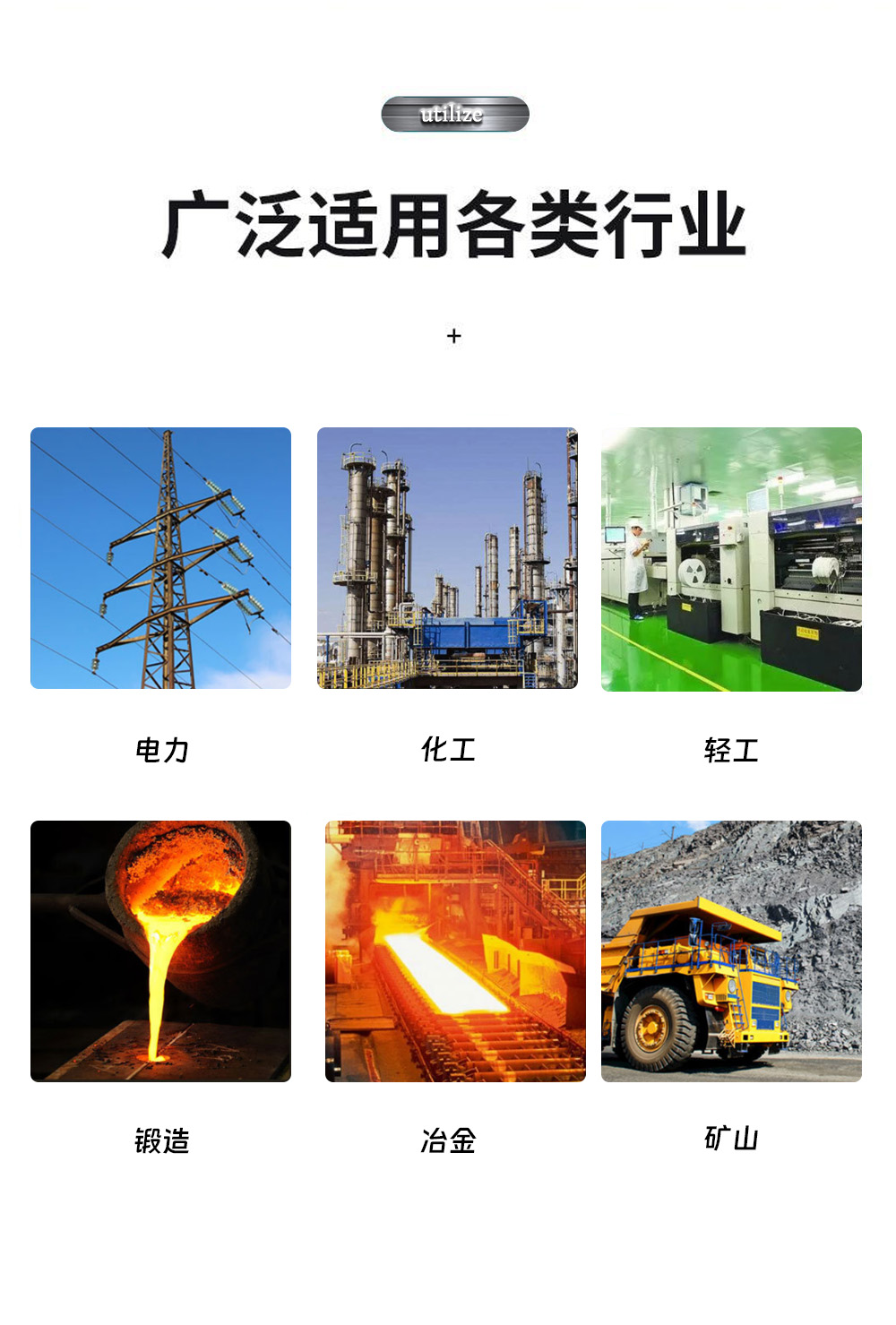

XVB series vibration motors are widely used in various vibration machinery, such as vibration feeders, vibration conveyors, vibration ore drawing machines, vibration shakeouts, vibration screening machines, vibration anti-blocking devices for silos, etc., involving power, building materials, coal, mining, metallurgy, chemical industry, light industry, casting and other industries.

XVB-135 - 8 Binhe three-phase asynchronous vibration motor is a kind of equipment commonly used in industrial production and belongs to a type of three-phase asynchronous vibration motor. The following is a detailed introduction:

XVB seriesvibration motorWidely used in various vibration machinery, such asvibrating feeder, vibrating conveyors, vibrating ore drawing machines, vibrating sand shaffer, vibrating screening machines, vibrating anti-blocking devices for silos, etc., involving power, building materials, coal,Mine, metallurgy, chemical industry, light industry, casting and other industries.

Appropriate coordination of excitation force and output force: It can meet the needs of different working conditions and effectively improve production efficiency.

Light weight and small size: Easy to install and use, saving equipment space.

Low noise: Less noise during operation, reducing noise pollution to the working environment.

fully enclosed structure: Suitable for working in a dust environment without explosion-proof requirements. It has a high level of protection, which can effectively prevent dust, debris, etc. from entering the interior of the motor and ensure the normal operation of the motor.

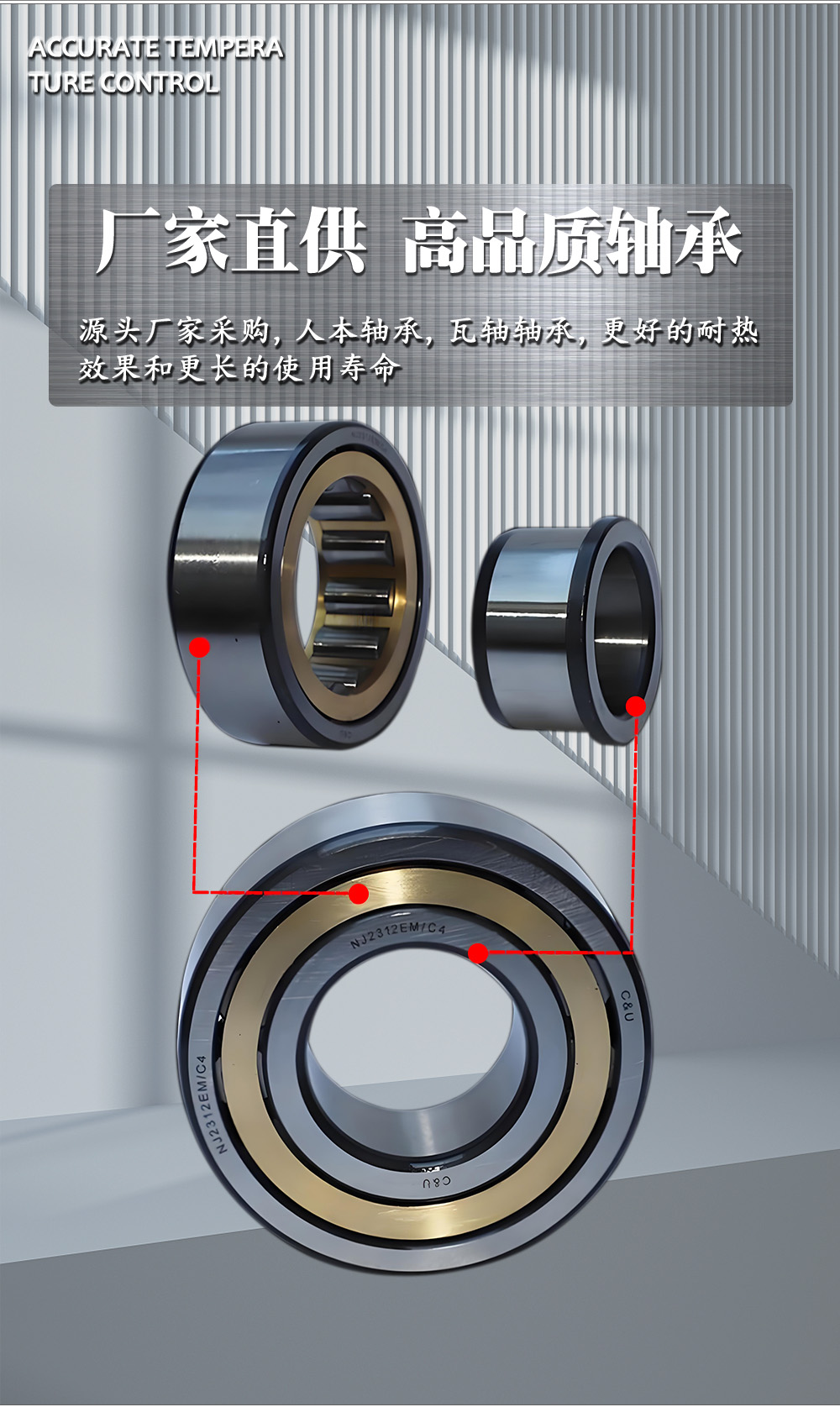

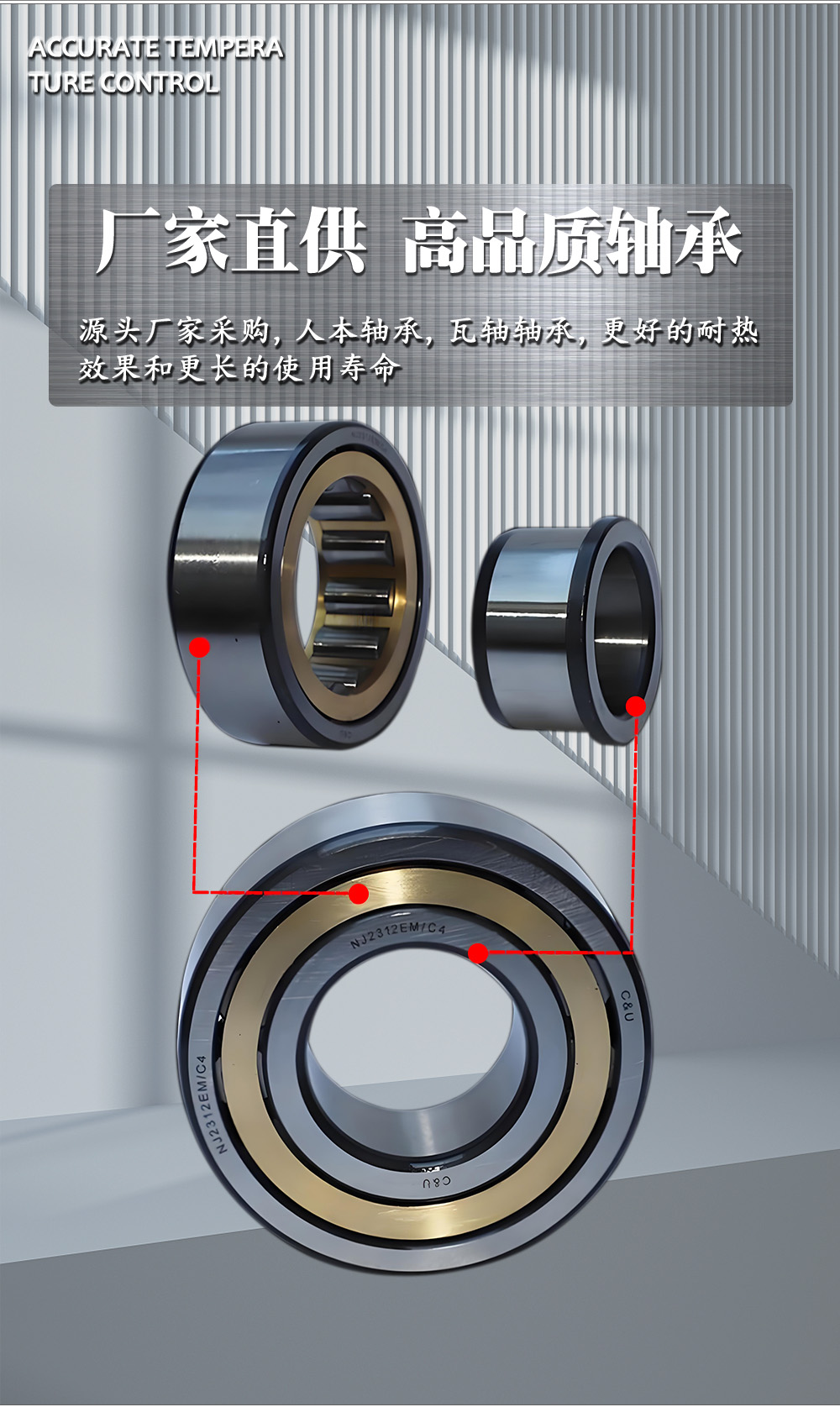

Long service life: It adopts high-quality materials and manufacturing processes, has good wear resistance and corrosion resistance, and can operate stably for a long time.

Exciting force can be adjusted steplessly: By adjusting the angle of the eccentric block, the magnitude of the exciting force can be adjusted steplessly, making it convenient for users to adjust according to actual needs.

Optimized electromagnetic design: The motor can generate a more uniform and stable magnetic field during operation, improving the operating performance and reliability of the motor.

Good cooling system: Ensure the stability and safety of the motor during long-term operation and effectively extend the service life of the motor.

Intelligent control technology: Remote monitoring and control of the motor can be realized, making it convenient for users to operate and manage.

When selecting an XVB series vibration motor, users should consider its application requirements, such as the required excitation force, working environment, dust and water resistance level, etc., to ensure that the selected vibration motor can meet specific process requirements. In addition, considering maintenance and operating costs, it is also very important to choose a vibration motor that is easy to maintain and operate.

XVB-135 - 8 Binhe three-phase asynchronous vibration motor is a kind of equipment commonly used in industrial production and belongs to a type of three-phase asynchronous vibration motor. The following is a detailed introduction:

XVB seriesvibration motorWidely used in various vibration machinery, such asvibrating feeder, vibrating conveyors, vibrating ore drawing machines, vibrating sand shaffer, vibrating screening machines, vibrating anti-blocking devices for silos, etc., involving power, building materials, coal,Mine, metallurgy, chemical industry, light industry, casting and other industries.

Appropriate coordination of excitation force and output force: It can meet the needs of different working conditions and effectively improve production efficiency.

Light weight and small size: Easy to install and use, saving equipment space.

Low noise: Less noise during operation, reducing noise pollution to the working environment.

fully enclosed structure: Suitable for working in a dust environment without explosion-proof requirements. It has a high level of protection, which can effectively prevent dust, debris, etc. from entering the interior of the motor and ensure the normal operation of the motor.

Long service life: It adopts high-quality materials and manufacturing processes, has good wear resistance and corrosion resistance, and can operate stably for a long time.

Exciting force can be adjusted steplessly: By adjusting the angle of the eccentric block, the magnitude of the exciting force can be adjusted steplessly, making it convenient for users to adjust according to actual needs.

Optimized electromagnetic design: The motor can generate a more uniform and stable magnetic field during operation, improving the operating performance and reliability of the motor.

Good cooling system: Ensure the stability and safety of the motor during long-term operation and effectively extend the service life of the motor.

Intelligent control technology: Remote monitoring and control of the motor can be realized, making it convenient for users to operate and manage.

When selecting an XVB series vibration motor, users should consider its application requirements, such as the required excitation force, working environment, dust and water resistance level, etc., to ensure that the selected vibration motor can meet specific process requirements. In addition, considering maintenance and operating costs, it is also very important to choose a vibration motor that is easy to maintain and operate.